The know-how of an expert machine operator in the palm of your hand

With our AI-Assistant you can get the most out of your machines. Get in touch to check if Optimyzer works for your machine.

20% higher productivity

Better cuts, less rework

Reduced gas consumption

15% higher productivity

50% lower plastic waste

Weld 45%-300% faster

Stronger, cleaner welds

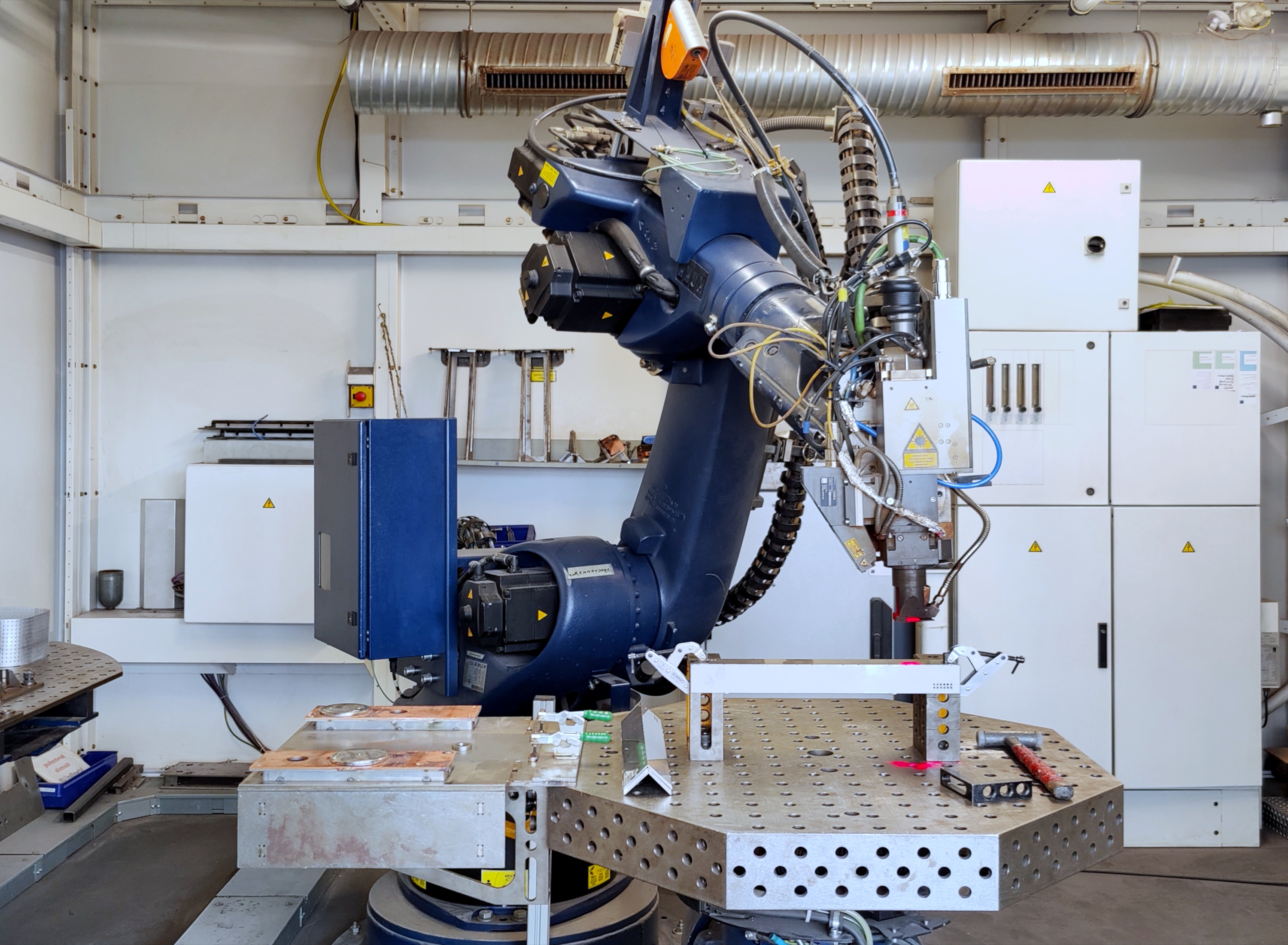

Operators find better machine settings for their production machines using Optimyzer, GaussML's intelligent copilot.

Faster production

You can increase your machine's productivity by as much as 50% with improved machine settings. With Optimyzer you can set up and finish your production faster.

Adapts to your demands

The "best" settings vary from case to case. Machine operators use Optimyzer to find the best settings in every situation. They decide if they want to focus on speed, cost or conserving resources and Optimyzer delivers.

What our customers say about Optimyzer

Thanks to Optimyzer, we were able to increase our laser cutting production capacity by around 20%. At the same time, we noticed a measurable improvement in energy efficiency. The smart Optimyzer is characterized by its ease of use.

Patrick Genkinger - H. Steinhart Metallwarenfabrik GmbH & Co KG

We struggled with the cutting quality of a new machine for several months. When the operators had almost given up making a good cut with this machine, we came across Optimyzer. That was a real game changer for us.

Asim Aghdiri - Ferrotec GmbH

Optimyzer helped us find better settings in under one hour. With those settings, we cut 66% faster and obtained a much better quality than before.

Marcel Bürkle - HAIMERL Lasertechnik

How Optimyzer benefits your factory floor

With Optimyzer, any machine operator is an expert

Machine operators use Optimyzer to get the best settings specifically tailored for their machine and their material, under any environmental conditions.

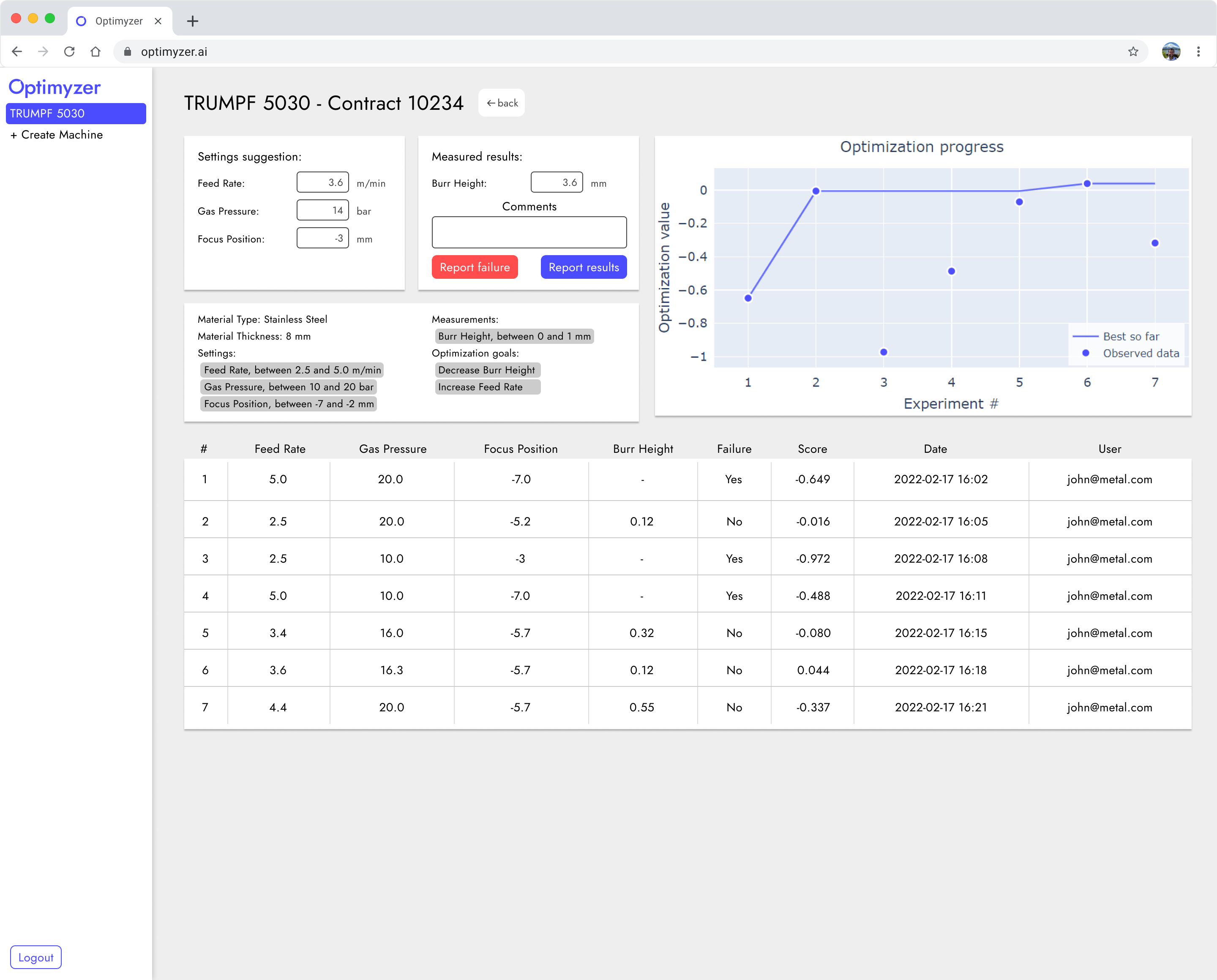

AI-based optimization in minutes

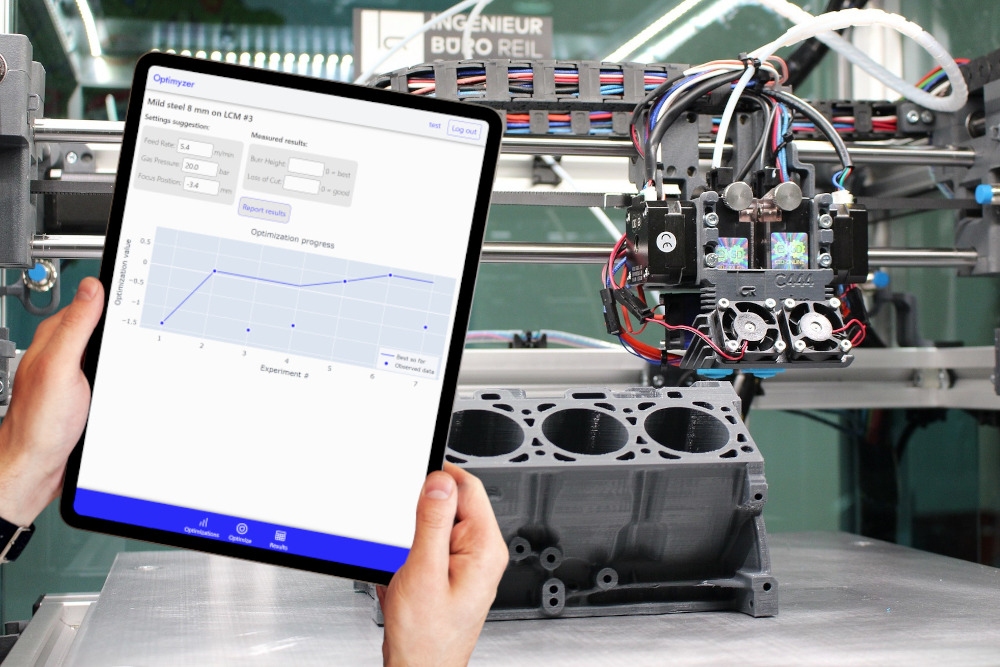

Not all state-of-the-art Artificial Intelligence solutions need months-long projects and gigabytes of data to deliver a return on investment. Optimyzer does that within minutes. You don't need any additional sensors or special connectors. All you need is an internet-connected device.

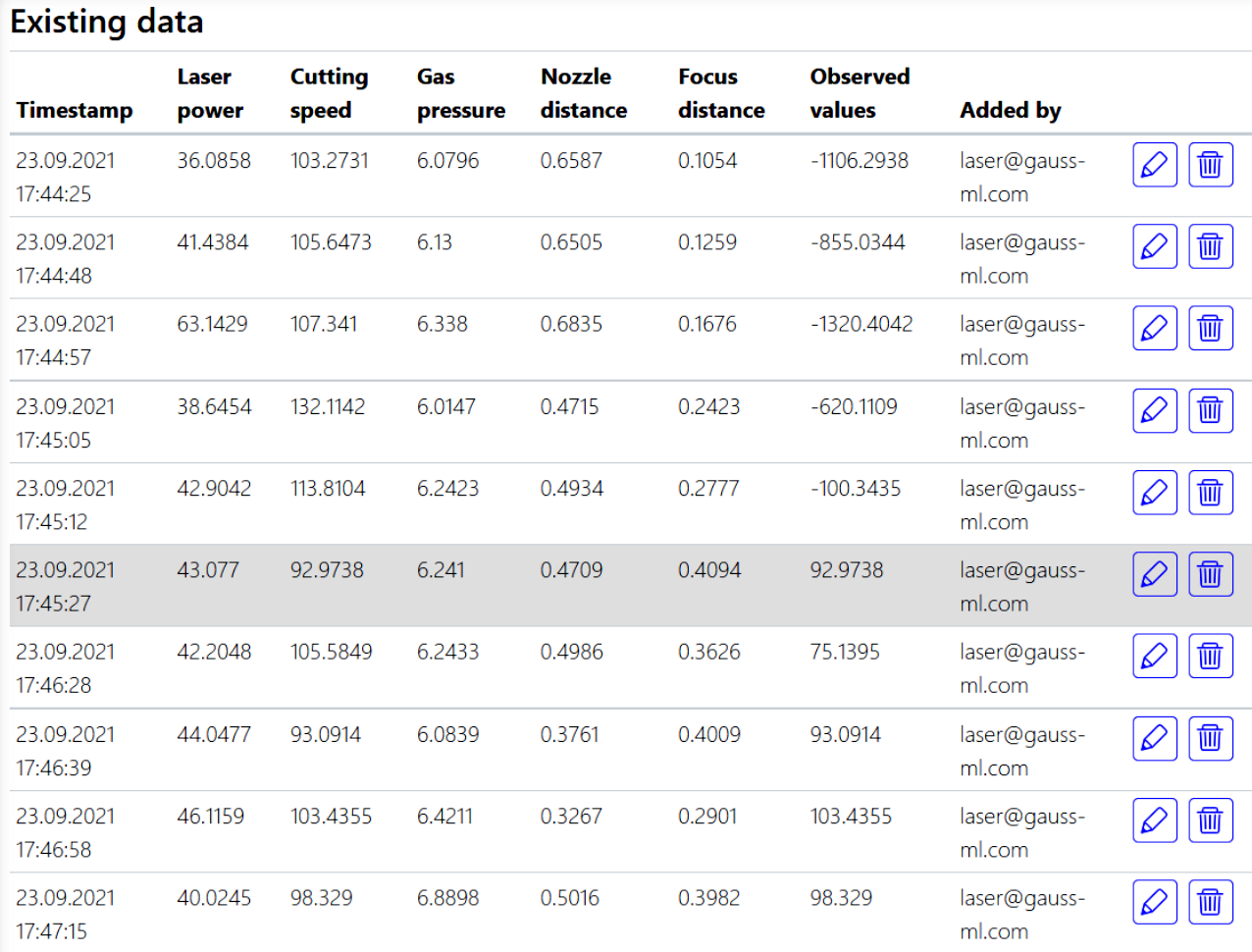

Historical settings database

Keep track of the settings that you tried out and how well they worked. The knowledge stays with your company and doesn't depend on a single expert knowing the machine in and out.

Read our Case Studies

Frequently Asked Questions

Optimyzer is an AI copilot that guides you to the best parameters for your machines, improving productivity, quality, and efficiency. It is not a tool for automated quality control or predictive maintenance. Optimyzer relies on feedback from your operators, engineers and any monitoring systems you'd like to use.

Optimyzer is best for manufacturers striving to increase machine productivity, reduce rework, and lower resource consumption. Ask yourself, "How much would I benefit from a 10% productivity boost or lower scrap rate?" If the answer exceeds €10,000 annually, Optimyzer can deliver significant ROI for your company.

Clients often achieve a 10-20% boost in productivity, reductions in rework, and significant material savings. For example: Optimyzer achieved a 10% cycle time reduction and zero defects in Coca-Cola's plastic injection molding process, it helped increase the output of laser cutting machines by 16% and eliminated rework efforts on welding robots.

You can start using Optimyzer within minutes. Simply have your machine, an operator, and a tablet with internet access ready. Most manufacturers see benefits in the first week, with a 10x ROI within the first year.

Optimyzer doesn't require the large investment typically associated with AI implementations. Our "small data" approach starts producing results from day one, without the need for extensive historical datasets or complex infrastructure.

Manufacturers leveraging Optimyzer typically see a 5-10x ROI. For example, optimizing a laser cutting machine can unlock €50,000 of additional annual productivity with 15% higher throughput. Optimyzer subscriptions are designed to deliver immediate value and scale with your needs.

Optimyzer has demonstrated significant results across various machines, from laser cutters and injection molders to welding robots and machining centers. Companies across industries use Optimyzer to optimize a wide range of processes. If you're unsure whether Optimyzer is right for your machine, contact us for a free consultation.

Yes, Optimyzer adapts to each material, product and operating conditions, quickly finding the best parameters to maximize quality and productivity. This flexibility is one of its strengths, especially for operations with diverse production requirements.

Optimyzer is a tool to get the most out of your machine all the time, not just when problems arise. Use it to fine-tune parameters for any material or part, increasing productivity, reducing rework and scrap, and optimizing resource consumption.

Optimyzer's interface is user-friendly, and operators generally need less than an hour of training to get started. It's designed to empower operators to achieve expert-level results, whether they're experienced or new to the role.

We highly value data security and follow industry best practices to protect your manufacturing information. Each optimization you run helps build knowledge about your specific machine to help you reach your goals ever faster. The data you input during optimizations is only available to your organization and is never shared with other customers.

Optimyzer works without any previous dataset, a direct machine connection, or additional hardware. Our unique “small data” approach helps you achieve rapid results with minimal setup.

GaussML provides comprehensive support, training, and regular updates. Our team ensures you get the most out of Optimyzer from day one and continue to see improvements as your processes evolve.

GaussML's "small data" technology enables Optimyzer to deliver impressive improvements within just a few experiments. Optimyzer's task is twofold: to quickly learn how your machine works and find the optimal process parameters in as little time as possible. The more it explores, the better it gets - often delivering outstanding results after just 2 or 3 parameter suggestions.

Unlike traditional methods such as Design of Experiments (DOE) that require statistical expertise and numerous experiments, Optimyzer delivers superior results with fewer trials and minimal technical knowledge. Optimyzer typically requires 10-30x fewer experiments to achieve better outcomes.

Our AI-driven approach adapts in real-time based on feedback, continuously refining its understanding of your specific machine behavior. This makes process optimization accessible to operators without specialized training, saving valuable production time while delivering consistently better results.